Service +31 (0)184 410555

Emmtec, a power supplier, uses a 31.250 kVA generator to supply power to businesses in Emmen. Bakker Repair + Services inspects this generator periodically, in order to keep their generator in the best condition.

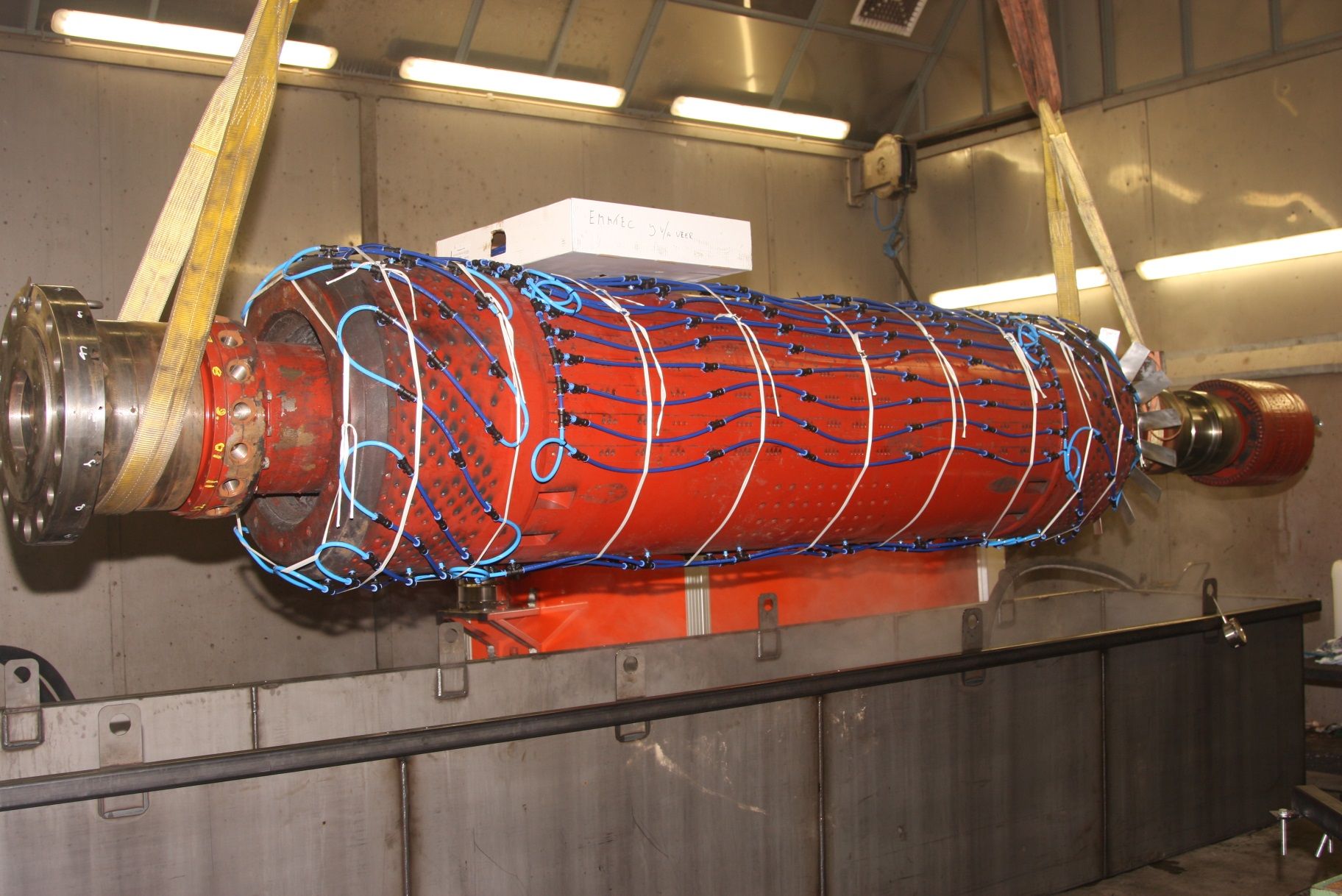

While performing a diagnostic measurement on the generator, Bakker Repair + Services detected that the turbo rotor was strongly contaminated. This resulted in low resistance. In consultation with Emmtec, we decided to disassemble the generator and to clean the 26 MW turbo rotor at Bakker Repair + Services’s workshop.

Our service engineers disassembled the turbo rotor quickly and efficiently on site, using tools that were specially created for this task.

To clean the turbo rotor, we immersed it in a bath filled with water and detergent. A custom designed air flow system cleaned the ventilation holes of the turbo rotor with air bubbles. Therefore air tubes were mounted on the turbo rotor. Afterwards, we dried the turbo rotor in our dry oven. After cleaning, the resistance increased significantly.

We transported the turbo rotor back to Emmtec and reassembled the generator on site.

Project scope:

Specs:

31.250 kVA generator

26 MW turbo rotor

Reference Emmtec

(216Kb)