Service +31 (0)184 410555

Minimize downtime: A brand new tailor made generator, electric motor or transformer has a long delivery time. Rewinding is the solution to start production again rapidly, reducing production loss to a minimum. We are standby 24/7.

Adjust to your needs: While we are rewinding, we can directly make adjustments to your generator, electric motor or transformer in order to create a perfect with your application.

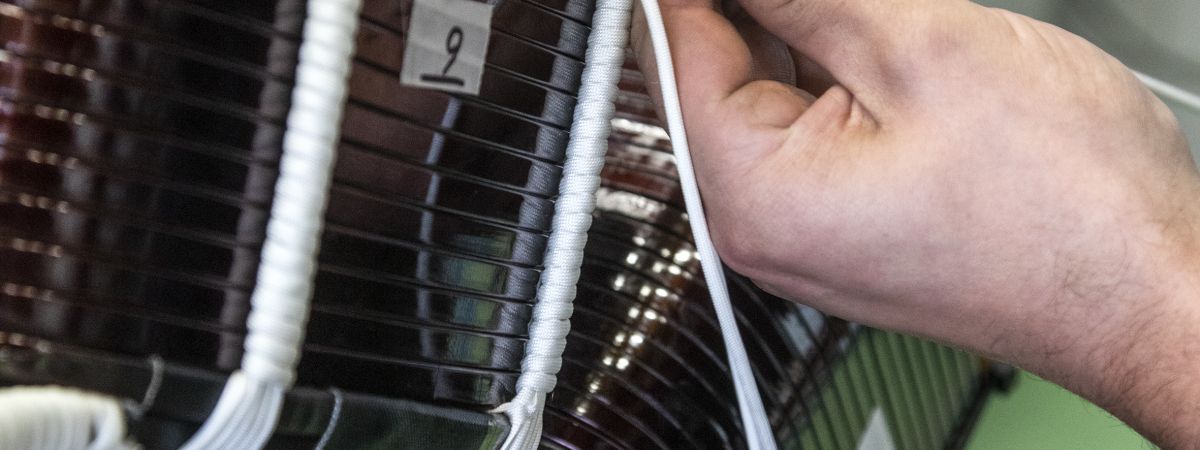

The Rewinding shop of Bakker Repair + Services is designed to rewind both high and low voltage electromotors, generators and transformers with a quick delivery time and high quality. Our skilful rewinders have extensive knowledge on rewinding all brands and types of motors and generators.

We are an authorized service provider for:

Bakker Repair + Services can manufacture AC and DC coils. Our vast stock enables us to quickly create the required components to skillfully rewind your machine.

Bakker Repair + Services is equipped with professional tools to restore, renew and test lamination and collectors.

During the rewinding process multiple tests are performed on set times to ensure our quality. All rewound electromotors, generators and transformers will be conducted to a final test prior to being delivered to you.

Each rewound machine will be delivered with a test report in which all the executed work is described in full detail. The report also includes the results of the tests.

References

Click here to see our rewinding references.

In addition to our rewinding services Bakker Repair + Services offers a Testing facility, a Mechanical workshop, a Balancing department and we can perform Modifications.

Please contact our Account Manager

Robert van Slobbe

call +31 6 3036 1944

mail Send e-mail

Rewinding: